About

What is a Bucket Elevator?

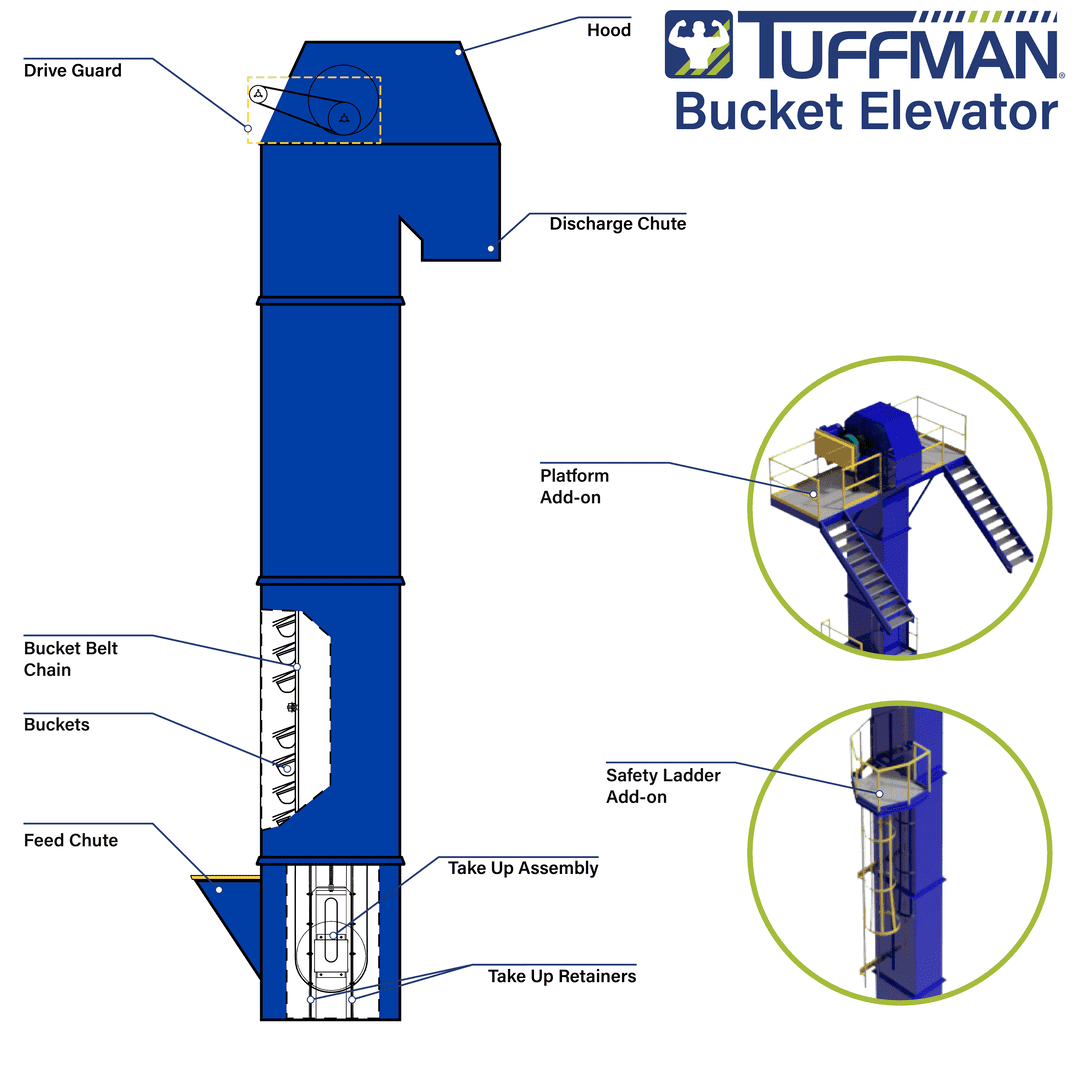

A bucket elevator is a vertically oriented piece of equipment with moving buckets inside. The purpose of the bucket elevator is to efficiently move material upwards and onto the next steps in the manufacturing process. The materials get fed into the inlet, are moved up vertically, and are then thrown out of the bucket and through the outlet using centrifugal force.

The TUFFMAN Bucket Elevator is especially efficient as it can move up to 175 tons per hour standard.

The Advantages of a Bucket Elevator

The TUFFMAN Bucket Elevator offers the advantage of moving high volumes of materials quickly and efficiently. It is also extremely durable in high-temperature environments and when moving heavy-duty materials such as pellets, gravel, sand, and more.

The vertical nature of bucket elevators helps optimize the use of space in your facility, decrease your footprint, and simultaneously increase throughput.

Another advantage of using a bucket elevator is its ability to be used indoors or outdoors, extending the amount of use you can expect from this equipment.

The benefit of working with TUFFMAN is experienced in every aspect of your journey. From the process of customizing your bucket elevator(s) alongside an experienced TUFFMAN engineer to seeing your facility run more efficiently than ever, you’ll be happy you chose TUFFMAN for your facility’s needs.

FAQ

How does a bucket elevator work?

A bucket elevator can work in one of three ways: centrifugal discharge, continuous discharge, or positive discharge. A centrifugal discharge bucket elevator works by using centrifugal force to move the contents of the bucket up and through the outlet. This type of bucket elevator is great for bulk materials such as sand, pellets, ash, shot, or powder.

What is the difference between a screw conveyor and a bucket elevator?

A screw conveyor moves bulk materials along a spiraling metal piece that looks similar to a screw. This piece of equipment can be in a horizontal, vertical, or inclined position and is usually more expensive than a bucket elevator. Bucket elevators move bulk materials via buckets moving along a vertical conveyor and are typically cheaper than screw conveyors.

Reviews

“The team at Tuffman Equipment have been great to work with throughout the whole processes of procuring and commissioning our trommel. All questions were quickly responded to which allowed me to build out the exact model with the options that we required. The equipment showed up on time and in great condition, it was immediately evident that the trommel has a great design and was well built with quality workmanship.”

Kris Heshka, VP – Operations

KF Hemp Corp.