Maximize your hemp and cannabis processing capabilities.

For the most cost-effective hemp and cannabis processing equipment, look no further than Tuffman Equipment. From belt conveyors to trommel screens, Tuffman can provide a solution for your hemp and cannabis processing needs, whatever your facility or operation requires.

Hemp Processing Equipment

What is Hemp?

Hemp is a booming industry in the United States. Industrial hemp, which is non-psychoactive, refers to the parts of the cannabis plant that are grown and processed specifically for industrial use. The appearance of hemp in medicinal products, skincare and beauty products, oil and vitamin supplements, building materials, biofuel, and even pet products is expanding in popularity.

With a rise in hemp products, the need for hemp processing plants to supply the demand is ever-growing. However, hemp is fragile, so processing it can be difficult to manage without the right equipment. Here at Tuffman, our products help hemp farmers and manufacturers maximize their hemp and cannabis processing capabilities, through our variety of high quality hemp processing equipment solutions. Below, we’ll walk through critical aspects of hemp processing and how Tuffman equipment will help in the process.

What Is Hemp Processing?

Hemp processing is the system of preparing a hemp product to be sold by distributors. Hemp processing for hemp fibers consists of trimming the buds off the stalks, drying the retted fiber, and curing the plant to ensure top results from a given hemp harvest. Hemp processing also preserves the seeds and stalks of hemp plants to be used in different applications.

Hemp Processing for Hemp Fibers

Trimming

The first step to hemp processing is trimming the hemp plant. When the plant is ready to harvest, farmers need to carefully trim the plant to preserve the bud. The goal in trimming hemp plants is to cut away the stalks from the top of the plant where the buds are contained while keeping the buds clean and intact. The buds contain the most valuable part of the hemp and are especially important if the goal is to extract CBD from a plant. However, the buds are incredibly fragile and can be easily crushed in the trimming process if not done carefully.

Drying

After the hemp is trimmed it should be removed to a drying facility immediately, where it may take up to a week to dry properly. Each step of the hemp processing system is important, but this step is especially crucial. If done incorrectly, the drying phase can ruin the product entirely.

The retted fibers in hemp buds need to be dried to 10-15% moisture to be usable. If the buds have too much moisture they easily mold, and if they don’t have enough moisture they are useless. To dry hemp buds correctly, ventilation, temperature, and humidity controls are a must.

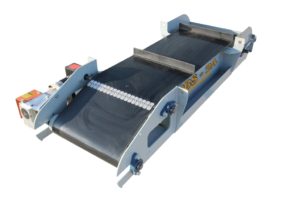

One important part of drying hemp buds is sorting by size, using equipment like trommel screens. Because of the different sizes of each hemp plant in a harvest, some will take longer to dry than others. Sorting the plants by size before laying the buds to dry allows you to easily remove the plants that are already dry and keep the plants that still need a few days to be dried properly.

To dry properly, it’s important to place the buds in a room that is constantly kept below 75 degrees Fahrenheit, and where the humidity can be controlled through ventilation. Ventilation helps to remove the wet air from around the bud and replace it with dry air. This process keeps the flower from browning and helps preserve the taste.

Curing

Hemp plants should be dried to the point where the little stalk remaining on the plant can easily snap in half. Curing can be done manually or with equipment to remove the last bits of moisture from the buds while keeping the bud’s original shape and color.

Hemp Processing for Seeds and Stalks

Stalks

After the bud is properly trimmed from the stalk, the stalk is also able to be used in manufacturing. Stalks need to be cleaned and dried, just like the buds, though the process isn’t as temperamental. After going through the retting process, stalks can be turned into fibers, chords, or cloths fermented and turned into ethanol or biofuel.

Seeds

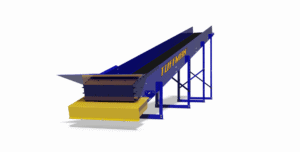

Hemp seeds can burst easily, and are therefore very delicate. Seeds also go through a drying phase before they are further processed. After a seed is dried, it is cleaned or dehulled to remove residue and the outer skin of the seed. Dehulling machines are useful in removing the outside shell from the hemp seeds. Gentle conveyors like Tuffman Belt Conveyors can help move the seeds from one phase to another to keep the fragile seeds from bursting.

Hemp Processing Equipment

Having reliable, high-quality hemp processing equipment is a crucial step in getting the best harvest possible from the many fragile parts of the hemp plant – whether you’re processing buds, stalks, or seeds. Here at Tuffman, we are invested in providing equipment to aid in the process of harvesting hemp, and are committed to helping you find the right equipment and systems for your setup.

Tell us about your hemp processing equipment needs using our form and receive a personalized demo of how we can meet your needs with high-quality hemp processing equipment from Tuffman.