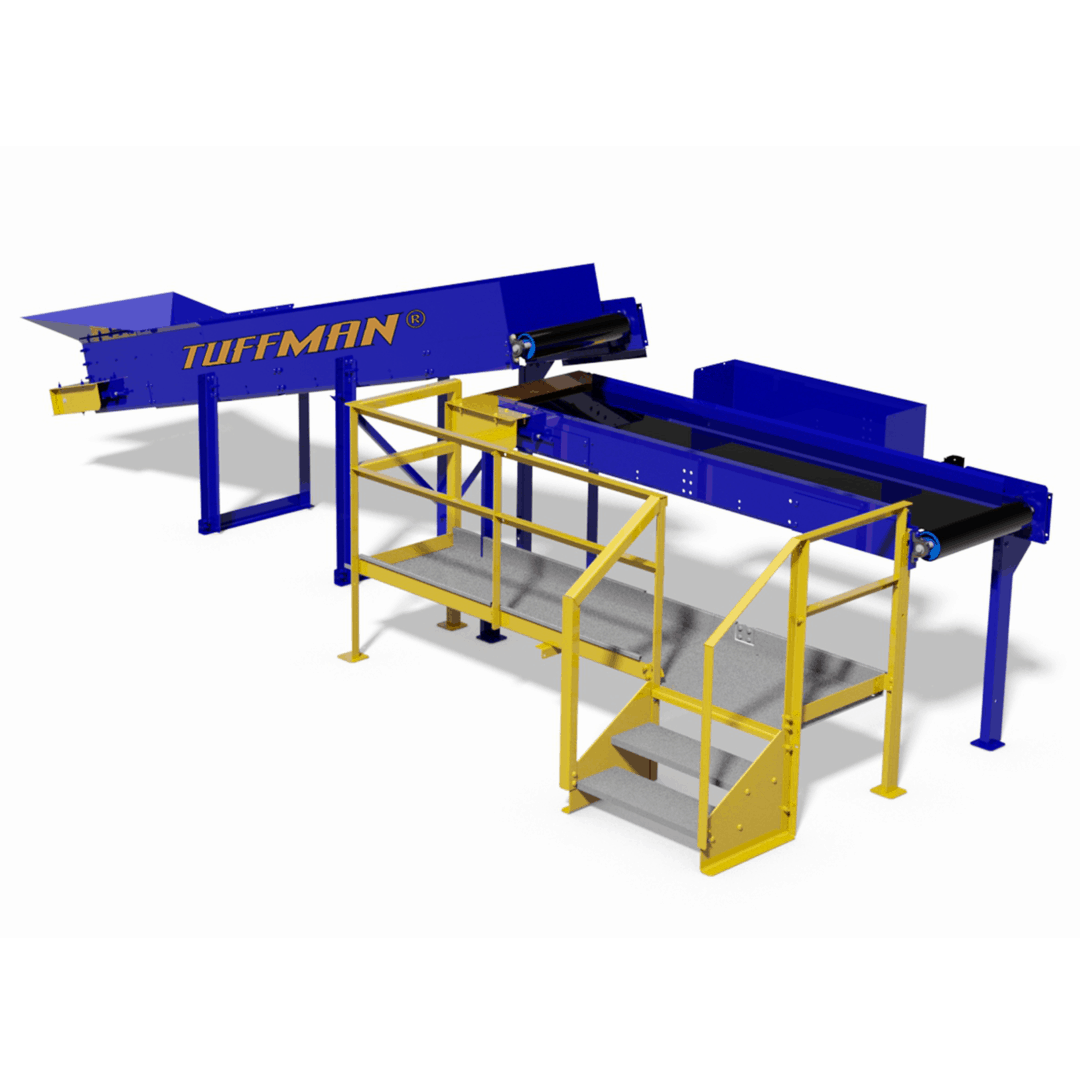

What is a Trommel?

What is a Trommel? Within the manufacturing machinery industry, rotary trommel screens play a vital role across various sectors. These innovative screening devices have proven to be highly effective in separating and classifying diverse materials. A trommel, also known as a rotary screen or drum screen, is a cylindrical screening device comprising a rotating drum…

Details